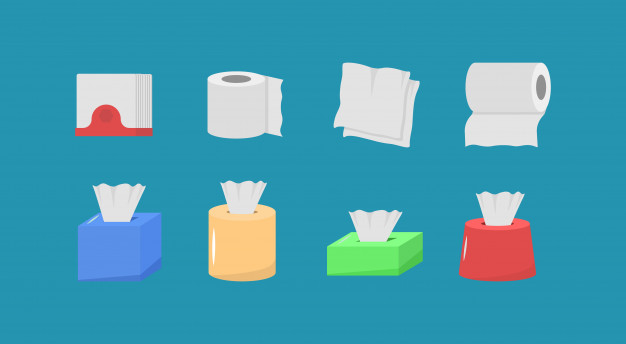

Thermal

paper rolls are widely used in daily life i.e. it is used in making the

receipts that you get from supermarket, or in shopping malls, or in restaurant,

or in coffee shops, etc. However, thermal paper rolls are also used as bus

ticket rolls as well as for the tickets of dispenser machines.

However, thermal

paper rolls and the thermal paper printer stand out for its low noise and quick

operation in ticketing system. Therefore, most of the buses and trains use

thermal paper roll for ticketing system.

Today, the Bus Ticketing Paper Rolls Manufacturer offers various paper sizes for bus ticketing system. For instance, there is 57mm wide paper roll which is small, convenient and cheaper and there is 80mm wide paper roll which is a bit costlier. Well, most of the bus system chooses 57mm wide paper roll and printers. Here are the popular sizes used in bus ticketing system.

·

57mm

x 17mt x 12mm

·

57mm

x 40mm x 12mm

·

57mm

x 50mm x 12mm

· Paper Weight: 48gsm, 55gsm, 60gsm

However, if

we talk about the latest trend of 2021, then coreless thermal paper rolls are

in trend because they offer great value for businesses. As we said, it’s a new

trend in 2021, so more companies switch to these paper rolls as they offer numerous

benefits such as savings on production and shipping costs. Here are the benefits

of using coreless thermal paper rolls as they can impact your business as a

whole.

·

Coreless Paper Rolls are Cost-Effective

Thermal paper rolls are not created equally. Well it means that the coreless papers come in different paper grades and lengths. In fact, the length of the coreless paper involves a little bit of mathematical computation as well hence if you order the same diameter of paper roll which you may be earlier doing, you will get a longer paper length because it is coreless and the core will be replaced with paper. This will maximize every length of it for printing receipts.

For example, a paper roll with the size of 57mm x 40mm has a 12-meter length with a standard plastic core but if we exclude the core, then the paper length will be 13 meters. This will make it longer and more valuable.

· Coreless Paper Rolls Save Space and

Transportation Cost

On the

contrary, if you choose the same length of paper roll, then you can get a

smaller diameter. Well this will save more space if you’re ordering in bulk.

For instance,

if the 80mm x 80 meters of thermal paper roll has a diameter of 80mm and a 12.7

mm of plastic core, then the diameter can be shortened to 77mm for the same

length at 80 meters as it will come without the core.

Hence, you

will save the carton cubic space in the containers for your orders. And, it

will also save you shipping costs because most of the logistic companies charge

their customers as per the cubic meter. And, with a shorter diameter, more

paper rolls can be imported in fewer containers while saving space.

· Coreless Paper Rolls are Environment Friendly

The cores in

the usual paper rolls are not recyclable because most of them are made of plastic.

However, most of the users throw them away once the paper rolls run out and

these cores will likely to be end up in a wasteland.

In fact, there can be even a worst case where these cores could go in water resources and pollute it, if not disposed properly. Well, being a business owner if you want to fulfill your social responsibility to the environment then go for coreless paper rolls.

·

Coreless Paper Roll Extends the

Lifespan of Printer

Coreless

thermal paper rolls are easy to install and they are also easy to maintain. Hence,

if one paper roll runs out, then you have no need to remove the old core before

installing a new one. Hence, it saves you much time and on top of that, the use

of paper core also accumulates some dust in the printer’s print head.

That’s why, with paper core, for maintenance you will need to clean it regularly. And, if you’re unable to do so then it will lead to poor print quality as the dust and dirt stuck in the print head will affect the quality of the printouts. Therefore, with coreless thermal papers, there will be less accumulated dust in the printhead and it will extend the lifespan of the printer.

Final Thoughts

Coreless

thermal papers are in trend now-a-days because they not only help you save

costs, but they are also environment friendly. And, when you ask a POS Paper Billing Rolls Manufacturer to

produce coreless rolls, then they will charge you less on the price per unit as

they don’t need to procure plastic cores.

Well, if you’re

thinking of going coreless, then look no further, let us know how your

requirements regarding the printing paper and we will help you with your next

purchase.

We are the

best Bus Ticketing Paper Rolls

Manufacturer and our paper rolls are manufactured by highly skilled and

experienced professionals with the top quality papers and advanced machines in

accordance with the set quality standards.

We offer paper rolls in various widths, layers, thickness, prints and lengths depending on the varied application requirements of our clients. And, the best part about us is that the paper rolls offered by us are highly appreciated among our clients for their features like high durability and unmatched quality.

0 Comments